5-Axis Machining Center

5-Axis Machining Center

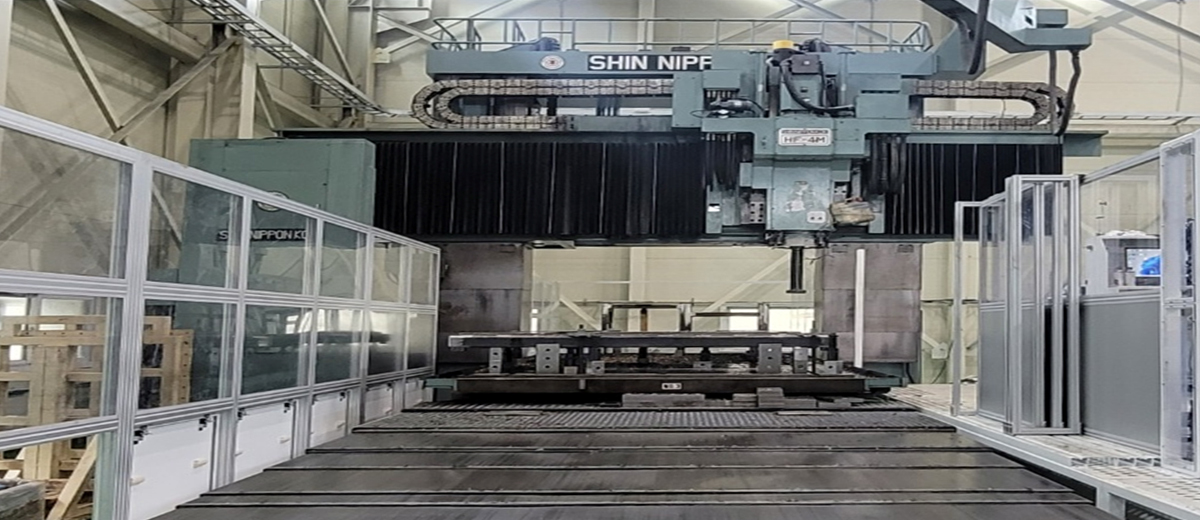

We have KAFO's double-column machining center and NIPPON's vertical machining center.

These machines can process five sides of a workpiece - front, back, left, right, and top - providing high precision and efficiency for large components.

By allowing machining of all sides except the bottom, they help reduce processing time.

KMC SERIES

KAFO’s Double-Column 5-Axis Machining Center

Features

- Designed with an LM guide system, this machine enables high-speed machining while maintaining high precision.

- It allows for simultaneous processing of all five sides with a single setup, ensuring accurate quality.

- The automatic angle head can tilt in 5-degree increments, accommodating a wide range of machining types.

Machine Specifications

| Spec | KMC6140 | KMC-4140 |

|---|---|---|

| X-Axis Travel Distance(Left-Right) | 6100 | 4100 |

| Y-Axis Travel Distance(Front-Back) | 4100 | 4000 |

| Z-Axis Travel Distance(Up-Down) | 900 | 900 |

| Spindle Distance(From Spindle to Table Surface) | 200-1100 | 200-1100 |

| Door Width | 3500 | 3200 |

| Table Dimensions | 3000-6100 | 2900-4100 |