Manufacturing Process

- STEP01

Design/Programming

- >

- STEP02

Laser Cutting

- >

- STEP03

Bending

- >

- STEP04

Welding/Alignment

- >

- STEP05

Machining

- >

- STEP06

Painting/Plating/Printing

- >

- STEP07

Product Assembly

- >

- STEP08

Quality Inspection

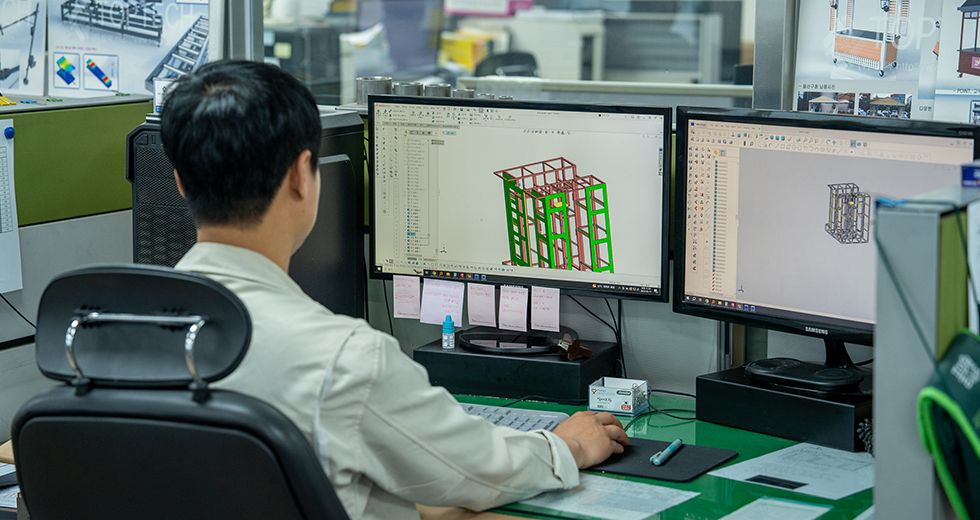

01 Design/Programming

- Blueprint Analysis and Product Drawing

- Product Design Using Programs

- Process Analysis and Equipment Selection

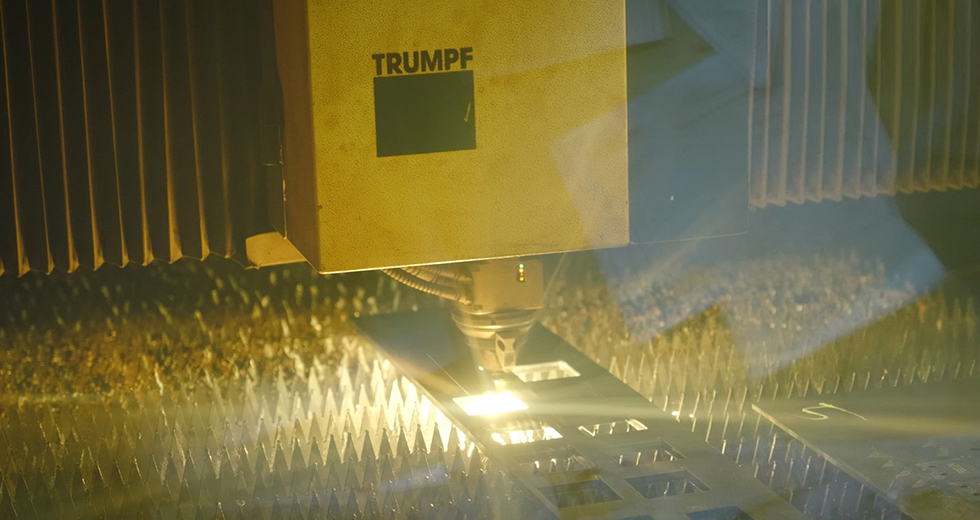

- Using a laser beam for cutting allows for easy processing of various shapes, resulting in smooth surfaces with no burrs.

- To generate the laser beam, liquefied nitrogen or liquefied carbon dioxide is used, depending on the material properties.

- Equipment Inventory : TruLaser Tube 7000, TruLaser 5030, TruLaser 3030

- A process that transforms material cut into flat shapes into the final product shape according to the design drawings.

- Various tools are used depending on the type of material and the bending shape.

- Equipment Inventory : TruBEND 5170, TruBend 7036, RG-50

Welding

- A stage in which the product's shape is completed by welding and assembling joints, reinforcements, and other components.

- Depending on the product and material characteristics, various welding methods are used, including electric welding, TIG (argon) welding, CO2 welding, and spot welding.

Correction

- A process for correcting distortions in the material caused by high heat during welding. This requires devices and fixtures to prevent distortion.

Painting

- Applied for corrosion resistance and to define the product's appearance.

- Depending on the product's use, both liquid and powder coatings are used.

Plating

- Applied for corrosion resistance and parts that require electrical conductivity.

- Types of plating include zinc, nickel, anodizing, and chromate, depending on the product material.

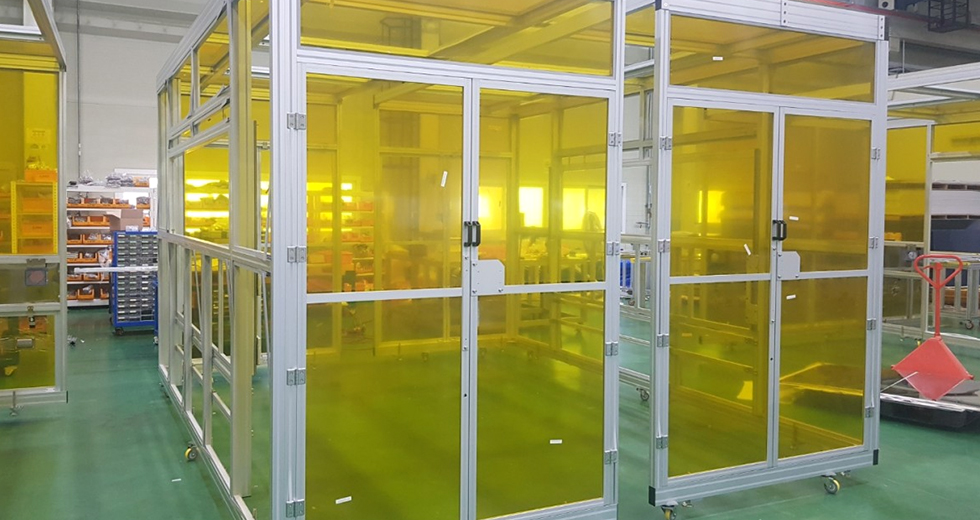

07 Product Assembly

- The process of completing the final assembly of the product.

(Assembling according to design drawings and customer specifications.)

08 Quality Inspection

- Checking the product's quality and cleaning condition.